Leveraging AI in Manufacturing for enhanced Safety, Efficiency and Innovation

The manufacturing industry is facing a critical juncture. Competition is fiercer than ever, demanding relentless optimization of production, unwavering commitment to quality, and an uncompromising dedication to worker safety. Fortunately, the rise of artificial intelligence (AI) presents a powerful solution to these pressing challenges. By harnessing the power of data-driven insights and fostering a robust safety culture, manufacturers can unlock unprecedented levels of efficiency, productivity, and competitiveness.

1. The Power of Data-Driven Insights

Manufacturing processes generate vast amounts of data – from machine sensor readings and production logs to inventory levels and customer feedback. Traditionally, analyzing this data has been a time-consuming and complex task. However, AI-powered solutions can now swiftly process and interpret this data, uncovering valuable insights that were previously hidden.

-

Predictive Maintenance: AI algorithms can analyze machine sensor data to predict potential equipment failures before they occur. This proactive approach minimizes costly downtime, reduces maintenance expenses, and ensures uninterrupted production flows.

-

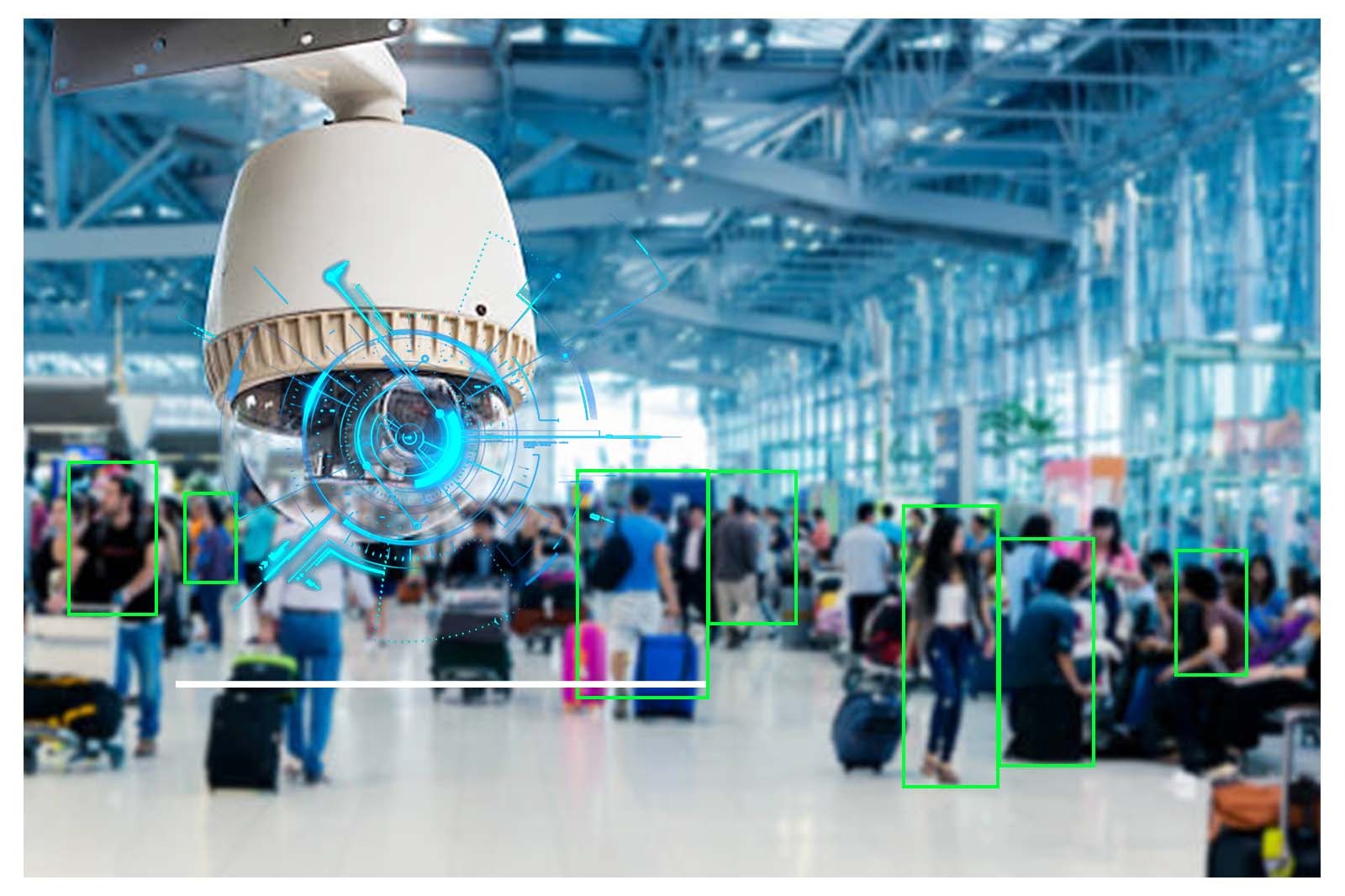

Quality Control Enhancement: AI-powered vision systems can inspect products for defects with unparalleled speed and accuracy. This eliminates human error, reduces waste, and ensures consistent product quality that meets stringent customer expectations.

-

Supply Chain Optimization: AI can analyze historical data and market trends to optimize inventory levels, predict demand fluctuations, and streamline logistics. This results in reduced inventory costs, improved order fulfillment, and enhanced customer satisfaction.

-

Process Optimization: By analyzing production data, AI can identify bottlenecks and inefficiencies in the manufacturing process. This allows for targeted improvements, such as optimizing production schedules, adjusting resource allocation, and streamlining workflows.

2. Cultivating a Culture of Safety

A safe and healthy work environment is not only a moral imperative but also a critical factor in ensuring business success. A strong safety culture fosters a proactive approach to risk management and empowers employees to prioritize safety in all their actions.

-

AI-Powered Safety Solutions:

-

Real-time Risk Assessment: AI algorithms can analyze real-time data from sensors, cameras, and wearables to identify potential hazards and alert workers to imminent dangers.

-

Incident Prediction: By analyzing historical safety data, AI can identify patterns and predict potential incidents, allowing for proactive interventions and preventative measures.

-

Ergonomic Analysis: AI-powered tools can analyze worker movements and identify ergonomic risks, minimizing the risk of musculoskeletal injuries.

-

Real-time Risk Assessment: AI algorithms can analyze real-time data from sensors, cameras, and wearables to identify potential hazards and alert workers to imminent dangers.

-

Employee Empowerment:

-

Safety Training and Education: AI-powered platforms can deliver personalized safety training programs, ensuring that all employees have the knowledge and skills necessary to work safely.

-

Incident Reporting and Analysis: AI can facilitate the efficient reporting and analysis of safety incidents, allowing for quick identification of root causes and the implementation of corrective actions.

-

Employee Feedback and Engagement: AI-powered platforms can gather employee feedback on safety concerns and provide a platform for open communication and collaboration on safety initiatives.

-

Safety Training and Education: AI-powered platforms can deliver personalized safety training programs, ensuring that all employees have the knowledge and skills necessary to work safely.

3. Implementing AI Solutions

Successfully implementing AI solutions in a manufacturing environment requires a strategic approach.

-

Data Collection and Integration: Establish robust data collection processes and ensure seamless data integration across various systems.

-

Pilot Projects: Start with small-scale pilot projects to test and refine AI solutions before widespread implementation.

-

Skill Development: Invest in training and development programs to equip employees with the necessary skills to work with AI technologies.

-

Collaboration: Foster collaboration between IT departments, operations teams, and safety professionals to ensure successful AI implementation and integration.

4. The Future of Manufacturing

By embracing data-driven insights and prioritizing safety, manufacturers can gain a significant competitive advantage. AI-powered solutions offer the potential to:

-

Increase Productivity and Efficiency: Streamline operations, reduce waste, and optimize resource utilization.

-

Enhance Product Quality: Ensure consistent product quality and minimize defects.

-

Improve Worker Safety: Create a safer and healthier work environment for employees.

- Gain a Competitive Edge: Differentiate themselves in the market and achieve sustainable growth.

The future of manufacturing lies in embracing innovation and leveraging the power of technology. By embracing AI and cultivating a strong safety culture, manufacturers can unlock their full potential and thrive in an increasingly competitive global market.

Video Analytics for Workplace Safety: What It Is and Why Your Business Needs It?

How Businesses Identify the Best Image Processing Company in India for Long-Term Success?

How to Identify the Best Video Analytics Company in India for AI-Driven Surveillance?

Best Video Analytics Company in India: A Complete Buyer’s Guide for Enterprises

AI in Predictive Analytics: How Businesses Can Prepare for the Future Today?

Why AI-Powered Video Analytics Is Becoming Essential for Modern Enterprises?

How AI and Data Analytics Are Helping Businesses Make Smarter Decisions?

Why Traditional CCTV Fails in Real-Time Threat Detection?

Video Analytics vs AI Surveillance – What Most Businesses Get Wrong?

Best Computer Vision Company in India for Businesses of All Sizes

Choosing the Best Video Analytics Company in India: Key Points to Check

From Watching to Protecting: How Video Analytics Ensures Workplace Safety?

Beyond Human Eyes: How Computer Vision is Transforming the Next Generation of Workplace Safety?

When Cameras Start Thinking: How AI Is Transforming Modern Surveillance?

Can Predictive Analytics Really Help Your Business Grow?

From Cameras to Clarity: How Enterprises Turn Raw Footage into Real-Time Business Intelligence?

Why Edge + AI Is the Future: Real-Time Intelligence for a Smarter, Safer Enterprise?

Smart Solutions Behind Mega Infrastructure: Making Complexity Look Easy

Is Your Workplace Really Safe? Discover How Smart Surveillance is Changing Safety Standards

Curious How AI Can Simplify Finance? Explore Compliance, Risk, and Seamless Integrations

How AI Video Analytics is Transforming Large Infrastructure, Ports, Airports, and Smart Cities?

Retail Revolution: How AI Powered Video Analytics Can Drive Success